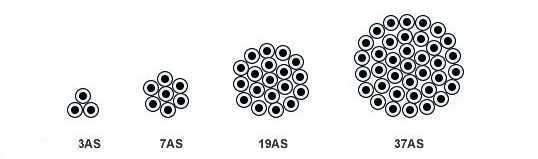

Galvanized steel wire strand can be supplied in single wire, three wire, seven wires , nineteen wires, thirty-seven wires. Its galvanized layer is bright and firm with strong corrosion-resistance, using hot dip galvanized vertical process, to ensure the thickness of zinc layer. As the core skeleton material of power cable, it directly serves the construction and renovation of power supply and power grid, and has the advantages of corrosion resistance, high strength, good elongation and high cost performance. Products are widely used in hanger, suspension, communication wire, overhead power line, cable steel core and fixed object tether, etc.

section structure: 3 wires, 7wires, 19wires, 37wires

| Wire diameter | Minimum Coating Mass (g/m2) | ||

| Class A | Class B | Class C | |

| 1.6 mm-1.90mm | 210 | 420 | 630 |

| 1.90mm-2.30mm | 220 | 440 | 660 |

| 2.30mm-2.70mm | 230 | 460 | 690 |

| 2.70mm-3.10mm | 240 | 480 | 720 |

| 3.10mm-3.50mm | 260 | 520 | 780 |

| 3.50mm-3.90mm | 270 | 540 | 810 |

Tensile strength is used to specify the breaking force of steel wire, can be divided into three levels.

| Wire diameter | Stress at 1% extension (Mpa) | |||

| Class A | Class B | Class C | Extra-High | |

| 1.6 mm-2.30 mm | 1310 | 1240 | 1170 | 1560 |

| 2.3 mm-3.05 mm | 1280 | 1210 | 1140 | 1560 |

| 3.05 mm-3.6 mm | 1240 | 1170 | 1100 | 1560 |

| 3.6 mm-4.8 mm | 1170 | 1100 | 1070 | 1560 |

| Wire diameter | Tensile strength (Mpa) | |||

| Class A | Class B | Class C | Extra-High | |

| 1.6 mm-2.30 mm | 1450 | 1380 | 1310 | 1770 |

| 2.3 mm-3.05 mm | 1410 | 1340 | 1280 | 1770 |

| 3.05 mm-3.6 mm | 1410 | 1340 | 1280 | 1770 |

| 3.60mm-4.80mm | 1380 | 1280 | 1240 | 1770 |

| Wire diameter | extension (%) | ||

| Class A | Class B | Class C | |

| 1.6 mm-2.30 mm | 3 | 3 | 3 |

| 2.3 mm-3.05 mm | 3.5 | 3 | 3 |

| 3.05 mm-3.6 mm | 4 | 3 | 3 |

| 3.60mm-4.80mm | 4 | 4 | 4 |

We have many kinds of steel raw material to choose from, and the steel material can be treated with lead hardening to achieve different strengths. The following table shows the chemical composition of steel .

|

Strength level |

% C |

% P |

% Mn |

% Si |

%S |

|

General |

0.45~0.50 |

0.032 |

0.5 ~1.00 |

0.10~0.34 |

0.041 |

|

High |

0.59~0.63 |

0.035 |

0.5 ~1.10 |

0.10~0.35 |

0.045 |

|

Extra-High |

0.65~0.83 |

0.035 |

0.5 ~1.10 |

0.10~0.35 |

0.045 |

Our company has passed ISO 9001 and ISO/TS 16949 quality management system certification, all the raw materials and semi-finished products are tested and recorded. Every step from raw material to finished products can be traced.

Adding value to your business is our ultimate goal. Please give us a call or leave us a message, our professional sales engineers will get in touch with shortly.